Struggling with bulk orders that disappoint your customers or fail under pressure? You’re likely making one or more of these common purchasing mistakes.

Buyers often lose money and time by ignoring quality indicators like material, stitching, or size1 when purchasing moving bags in bulk.

These issues may seem minor, but they can cause major setbacks. Let’s break down the top mistakes—and how to avoid them.

Ignoring Material Quality: Why Fabric Strength Matters More Than Price?

Focusing too much on cost may tempt you to settle for weak fabrics—but the damage from a torn bag can cost far more in the long run.

Always prioritize high-strength, durable fabric like RPET or PP-woven2 over the cheapest option to prevent product failure.

Why Fabric Strength Directly Impacts Your Brand Reputation

In my experience working with overseas buyers, especially from supermarkets and promotional sectors, many focus on price first. But without quality, their orders often get returned or receive poor customer feedback.

Here’s a comparison table to show the common fabric types and their pros and cons:

| Fabric Type | Strength | Eco-Friendly | Cost Level | Best Use Case |

|---|---|---|---|---|

| RPET | High | Yes | Medium | Premium moving/storage bags |

| PP-Woven | High | Moderate | Low | Budget-friendly bulk orders |

| Non-Woven | Medium | Yes | Low | Light-duty moving or gifting |

| Nylon | High | No | High | Fashion-focused moving bags |

Before placing a bulk order, request swatches or samples to test the fabric quality in person. A sturdy material not only protects the contents—it protects your brand image.

Overlooking Stitching and Handle Reinforcement?

A bag is only as strong as its weakest stitch. Ignoring stitching methods can lead to tearing during shipping or customer use.

Ensure handles are double-stitched and reinforced with cross-stitching or bar tacks3 to support heavier loads.

Handle Failures Cause More Than Just Returns

Many clients I’ve worked with had bulk orders fall short due to poor stitching. Especially in logistics-heavy industries, a weak seam equals failed delivery.

Check these stitching methods when you inspect a sample:

| Stitching Method | Durability | Suitable For | Common Weakness |

|---|---|---|---|

| Single Stitch | Low | Lightweight items | Easily rips under pressure |

| Double Stitch | Medium | Standard loads | Better but still limited |

| Cross Stitch | High | Heavy-duty handles | Ideal for high-tension areas |

| Bar Tack Stitching | Very High | Industrial use | Hard to break even under strain |

Never assume all stitching is equal. Clarify your expected use case and load limits, and request construction photos or videos if possible.

Choosing the Wrong Size or Capacity for Your Needs?

Ordering too-small or oversized bags can lead to poor packing efficiency or waste, driving up logistics and storage costs.

Select bag dimensions based on your end-use scenario4—whether for home moves, retail display, or warehouse storage.

Size Inconsistency Can Wreck Your Entire Inventory Plan

One of our clients ordered thousands of bags for retail packaging, but failed to confirm the internal dimensions. The result? Products didn’t fit, and they lost both time and profit.

Use this sizing guide to avoid common errors:

| Bag Size (L x W x H cm) | Volume Capacity | Ideal Use Case |

|---|---|---|

| 60 x 30 x 30 | ~54L | Home moves or closet storage |

| 70 x 40 x 35 | ~98L | Retail returns or clothing |

| 80 x 50 x 40 | ~160L | Warehouse or bulk goods |

Confirm your size needs in liters or cubic measurements—not just flat dimensions. And always test with actual contents.

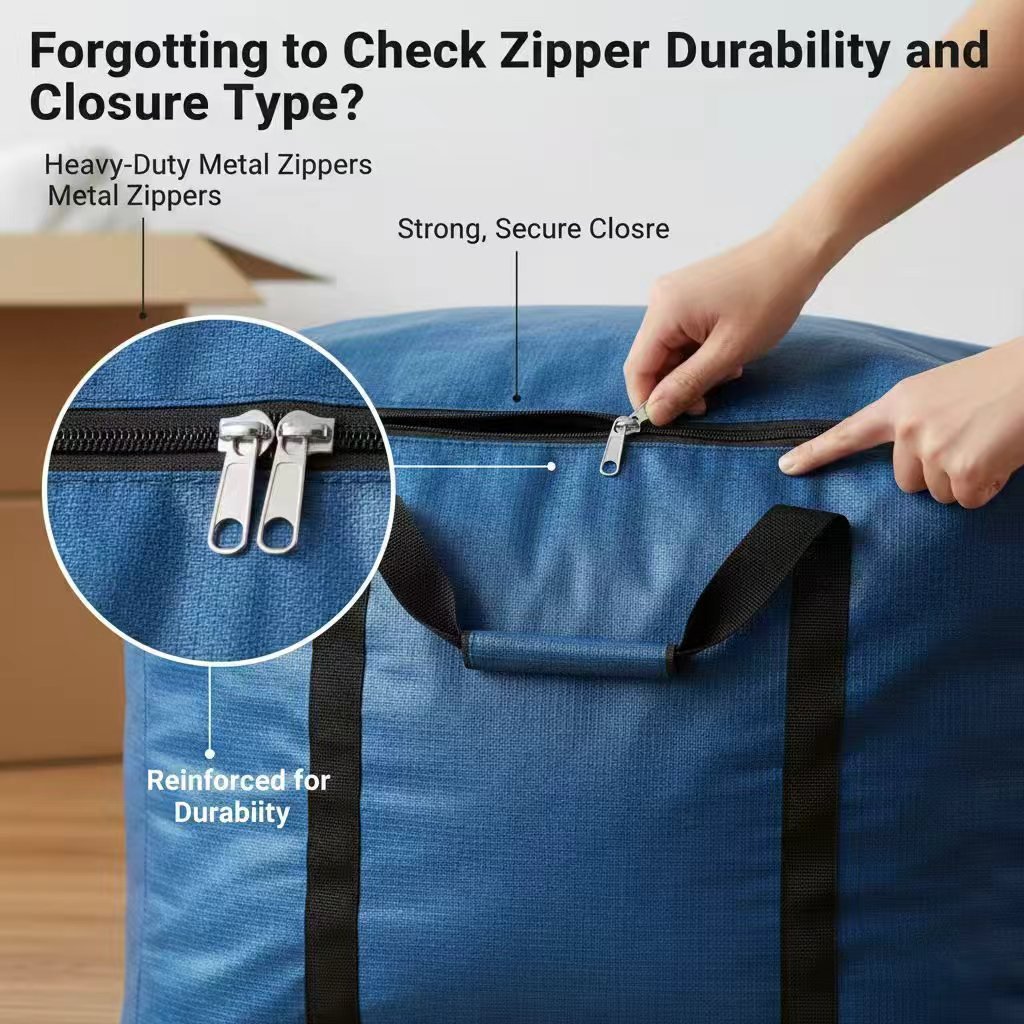

Forgetting to Check Zipper Durability and Closure Type?

You might overlook zippers, but they’re a critical failure point—especially during high-stress moving situations.

Choose industrial-grade zippers or YKK options5 to avoid mid-transport bag failures. Closure type should match the bag’s purpose.

A Broken Zipper Can Break Customer Trust

I’ve seen bulk orders get rejected at customs or retail warehouses simply because a few zippers failed during inspection. This led to emergency reorders and penalty fees.

Here’s a simple comparison chart:

| Closure Type | Security | Ease of Use | Recommended For |

|---|---|---|---|

| Nylon Zipper | High | Moderate | Long-distance transport |

| YKK Zipper | Very High | High | Premium products |

| Velcro Flap | Low | Very Easy | Light loads or quick access |

| Snap Button | Medium | Easy | Promotional use |

Don’t just test one sample—ask the supplier how many cycles the zippers have been tested for. Industrial standards often require 5,000+ cycles.

Not Asking About Weight-Bearing Tests or Load Limits?

If you’re skipping technical specs like load capacity, you’re risking bag failures that could damage goods or injure handlers.

Every reliable supplier should provide weight-bearing test data and certifications6 for their bags. Ask before placing bulk orders.

Load Limit Data Can Save You From Legal Headaches

In some regions, failing to meet safety or load standards can expose your company to compliance issues. A U.S. supermarket client once returned an entire shipment due to vague specs.

Request this data:

| Test Type | Purpose | Required Data |

|---|---|---|

| Load-bearing test | Max weight the bag can hold | kg or lbs |

| Drop test | Shock resistance during transit | Pass/fail criteria |

| Seam strength test | Measures resistance at seams | Force in Newtons or lbs |

| Certification compliance | Regulatory fit (e.g., REACH) | Valid test reports, dates |

Always ask for third-party test results, especially if you’re distributing in regions like the EU or North America.

Conclusion

Avoiding these five mistakes ensures your bulk moving bag purchase meets quality, size, and durability expectations—protecting both your brand and your profit.

-

Understand how poor quality control in material or sizing leads to returns and customer complaints. ↩

-

Learn why RPET and PP-woven fabrics outperform cheap alternatives in durability and eco standards. ↩

-

Discover how cross-stitching and bar tack techniques significantly increase handle strength. ↩

-

Avoid packing issues by choosing the correct bag size for logistics or retail applications. ↩

-

Ensure zippers match usage requirements with options like YKK for high-load conditions. ↩

-

Verify supplier credibility through third-party weight, drop, and seam strength certifications. ↩