Choosing the right non woven fabric bags manufacturer1 can feel overwhelming. Poor choices risk wasted money and missed opportunities.

A good manufacturer offers strong infrastructure, certified quality2, and reliable production to meet your business needs.

Let’s uncover what makes a factory truly worth working with.

Factory Infrastructure & Production Facilities – What Should You Look For?

A weak production base can lead to poor quality and delays. A strong infrastructure ensures stability and efficiency.

Look for modern workshops, organized layouts, and efficient production lines3 that match your order scale.

Understanding Production Facilities

A manufacturer’s infrastructure directly impacts output and quality. I’ve seen factories with poor layouts lose time just moving materials. On the other hand, a well-organized plant with dedicated sections for cutting, printing, and stitching keeps production smooth.

| Facility Feature | Why It Matters | Example Benefit |

|---|---|---|

| Multiple production lines | Higher output, less downtime | 5 lines producing different bag types |

| Separate QC areas | Prevents defective goods from moving ahead | Faster detection of faults |

| Climate control | Maintains fabric quality | No warping or moisture issues |

Material Sourcing & Quality Certifications – Why Are They Crucial?

Using substandard materials leads to low durability and failed certifications.

Ensure the factory sources certified, eco-friendly materials4 and can provide proof of compliance.

Certified and Sustainable Materials

I always request proof of certification before finalizing an order. Factories working with GRS, BSCI, or REACH standards5 show they value long-term relationships, not quick profits.

| Material Type | Certification Examples | Key Benefit |

|---|---|---|

| RPET fabric | GRS | Verified recycled content |

| Non woven PP | REACH | Safe for EU markets |

| Organic cotton | GOTS | Eco-conscious branding |

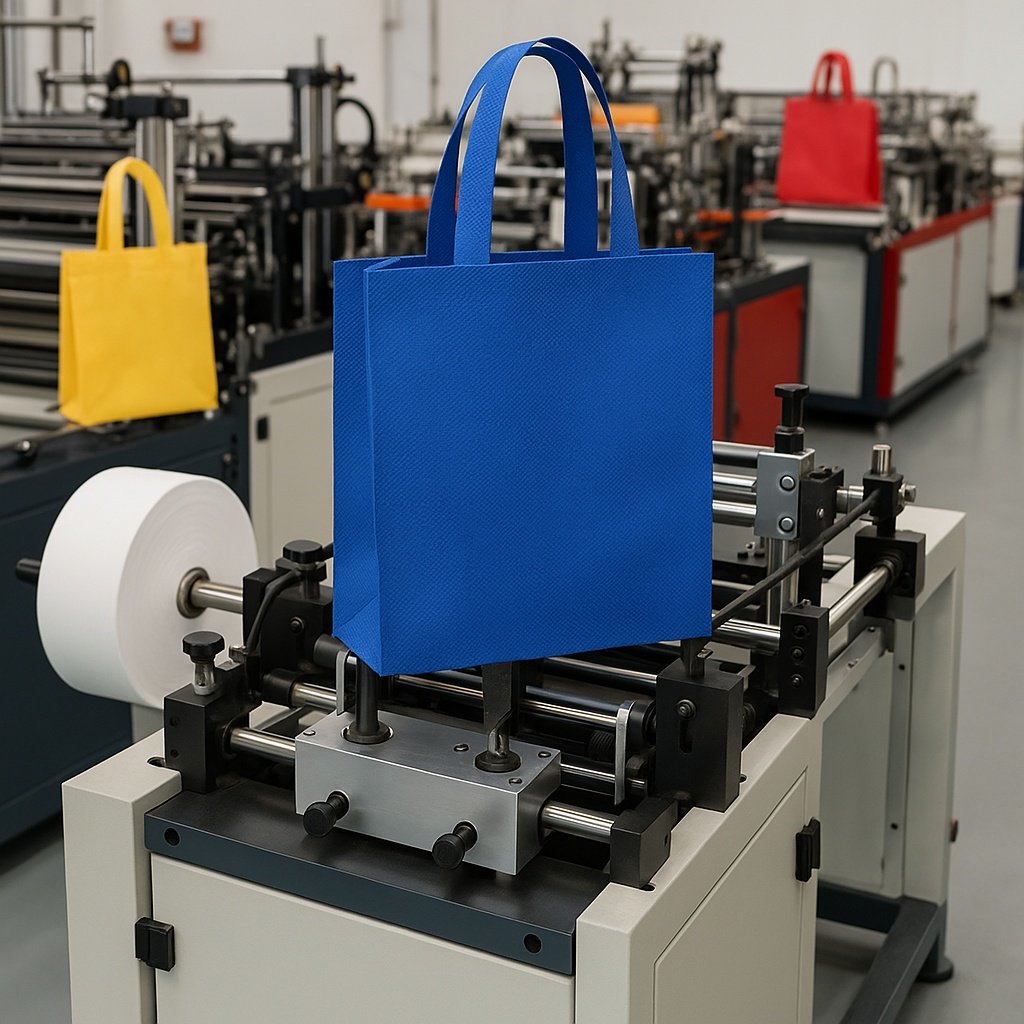

Essential Bag-Making Machinery – What Should a Good Factory Have?

Outdated machines slow down production and cause inconsistency.

A reliable manufacturer invests in modern bag-making machinery6 for cutting, printing, and stitching.

Machinery That Makes a Difference

During visits, I inspect the sewing machines, ultrasonic bonding units, and printing presses. A single machine breakdown can stall production for days if no backups exist.

| Machine Type | Purpose | Impact on Quality |

|---|---|---|

| Ultrasonic welding | Seam bonding without stitches | Stronger, cleaner seams |

| Automatic cutting | Precision fabric cutting | Reduces waste and errors |

| Screen printing unit | Applying designs/logos | Consistent brand presentation |

Quality Control & Inspection Procedures – What Should You Expect?

Skipping quality checks risks defective products reaching your customers.

Factories with multiple QC stages deliver consistent and defect-free bags.

Multi-Stage QC Process

I once worked with a supplier who only checked the final shipment — the result was a batch of misprinted bags. Now, I demand at least three inspection stages: incoming materials, mid-production, and pre-shipment.

| QC Stage | Purpose | Example Activity |

|---|---|---|

| Incoming check | Verify material quality | Fabric thickness test |

| In-process check | Detect defects early | Stitching inspection |

| Final check | Ensure order accuracy | Counting, measuring, packing review |

Customization & Design Options – What Can You Request?

Limited customization restricts brand identity.

A capable manufacturer offers logo printing, size adjustments, and unique design features7.

Expanding Brand Value Through Customization

When I supply to large retailers, I request Pantone color matching and multiple print positions. This flexibility boosts brand visibility and customer recall.

| Custom Option | Benefit | Example Use Case |

|---|---|---|

| Logo printing | Enhances brand recognition | Event giveaways |

| Custom sizes | Fits specific products | Wine bottle bags |

| Special handles | Improves comfort & appeal | Rope handles for luxury shopping |

MOQ, Sampling Process & Lead Times – What Should You Plan For?

Unclear MOQs and long lead times can disrupt sales cycles.

Know the minimum order quantity, sample approval process, and realistic delivery times8 before committing.

Planning for Production

For big buyers like supermarkets, I push for low MOQs during trial runs. The sampling stage is where adjustments happen — skipping it is a costly gamble.

| Factor | Typical Range | My Advice |

|---|---|---|

| MOQ | 500–5,000 pcs | Negotiate for flexibility |

| Sample time | 5–10 days | Approve before bulk order |

| Lead time | 25–45 days | Add buffer for holidays |

Export Capabilities & Production Capacity – How to Evaluate?

A factory with limited export experience may struggle with documentation and compliance.

Choose a manufacturer experienced in exporting to your target markets9.

Ensuring Smooth Exports

I once had a supplier who shipped late due to missing export paperwork. Now, I always verify if they handle customs clearance efficiently.

| Capability | Why It Matters | Example |

|---|---|---|

| Export licenses | Legal requirement | China’s export permit |

| Freight partnerships | Faster, cheaper shipping | Long-term freight forwarder deals |

| Large capacity | Meets big seasonal demand | 200,000 bags/month output |

Compliance with International Standards – Why Is This Important?

Non-compliance can block your goods at customs.

Verify that the manufacturer meets safety, labor, and environmental regulations10 for your destination market.

Avoiding Compliance Risks

For EU clients, REACH compliance is non-negotiable. For North America, I check CPSIA for children’s products. Skipping this check can result in seized shipments.

| Standard | Region | Focus Area |

|---|---|---|

| REACH | EU | Chemical safety |

| CPSIA | USA | Child product safety |

| BSCI | Global | Social responsibility |

OEM/ODM Service Support – What Benefits Can You Gain?

Factories without strong OEM/ODM11 support limit your ability to innovate.

Select a partner that can develop products from concept to mass production.

Building Your Product from Scratch

I worked with a factory’s in-house designer to create a unique folding shopping bag. It became one of my best sellers due to exclusivity.

| Service Type | Description | Advantage |

|---|---|---|

| OEM | Manufacturer follows your design | Full control over look & specs |

| ODM | Factory provides ready designs | Faster market entry |

Tips for Preparing a Factory Visit – How to Get the Most Out of It?

Visiting without a plan wastes time and misses red flags.

Prepare a checklist to evaluate facilities, processes, and compliance12 before you go.

Maximizing a Factory Visit

I always bring a camera, checklist, and sample from past orders to compare. This avoids surprises after production starts.

| Preparation Step | Purpose | Example |

|---|---|---|

| Arrange interpreter | Avoid miscommunication | Technical term clarity |

| Prepare questions | Save time during visit | Ask about defect rates |

| Inspect samples | Compare quality in person | Check stitching and print sharpness |

Conclusion

Choosing the right non woven fabric bag manufacturer requires checking facilities, certifications, customization options, compliance, and export readiness.

-

Learn how to choose the best non woven bag manufacturer for B2B supply. ↩

-

Understand why certified quality ensures consistent and safe production. ↩

-

Discover how production lines affect efficiency and delivery time. ↩

-

See why eco-friendly materials improve brand value and compliance. ↩

-

Learn the role of GRS, BSCI, and REACH in manufacturing. ↩

-

Explore how modern machinery boosts quality and reduces waste. ↩

-

Find out how customization options increase brand value. ↩

-

Learn why MOQs, sampling, and lead times matter in production planning. ↩

-

Understand the importance of export experience and capacity. ↩

-

See why compliance with international standards prevents customs issues. ↩

-

Find out how OEM/ODM services drive product innovation. ↩

-

Learn what to check during a factory visit for better decision-making. ↩