Leading paragraph:

You store bulky bedding, seasonal clothes, or inventory and waste time, space and money. Vacuum seal bags compress, protect and preserve—helping you reclaim room, save cost and stay organised.

Snippet paragraph:

Large vacuum seal bags reduce volume dramatically, protect items from dust and moisture, and extend freshness and shelf‑life when used properly.

Transition paragraph:

Let’s explore what problems they solve, how to choose, and how to use them well.

What Problems Do Large Vacuum Seal Bags Actually Solve?

Leading paragraph:

You face overflowing wardrobes, large shipping volume, and food spoilage. Vacuum bags help tackle these issues directly.

Snippet paragraph:

By removing excess air and sealing out moisture, vacuum bags save space, reduce spoilage and enhance storage protection1.

Dive‑Deeper

The “air problem” in storage

When bulky items lie unused, a lot of what you pay for is just air. Vacuum seal bags evacuate that air and reduce volume2. They also shield contents from dust, moisture, mould and pests.

The spoilage cost

For food items, oxygen and moisture drive spoilage and freezer burn. Vacuum sealing slows that, helping you save food and money.

| Limitations & risks | Risk | Why it matters |

|---|---|---|

| Fabric damage | Natural fibres or down may deform under long compression. | |

| Moisture & mould | If items aren’t dry before sealing, you trap moisture inside. | |

| Not long‑term fit for all | Some materials degrade under permanent vacuumed state. |

Takeaway: These bags are powerful tools—but match them to your items, use properly, and watch storage conditions.

Which Vacuum Seal Bag Should I Buy?

Leading paragraph:

Many sizes and specs exist. Choosing incorrectly may cost you in performance or returns.

Snippet paragraph:

The right bag depends on item size, material durability, reuse frequency3 and whether you’re storing goods or food.

Dive‑Deeper

Key features to check

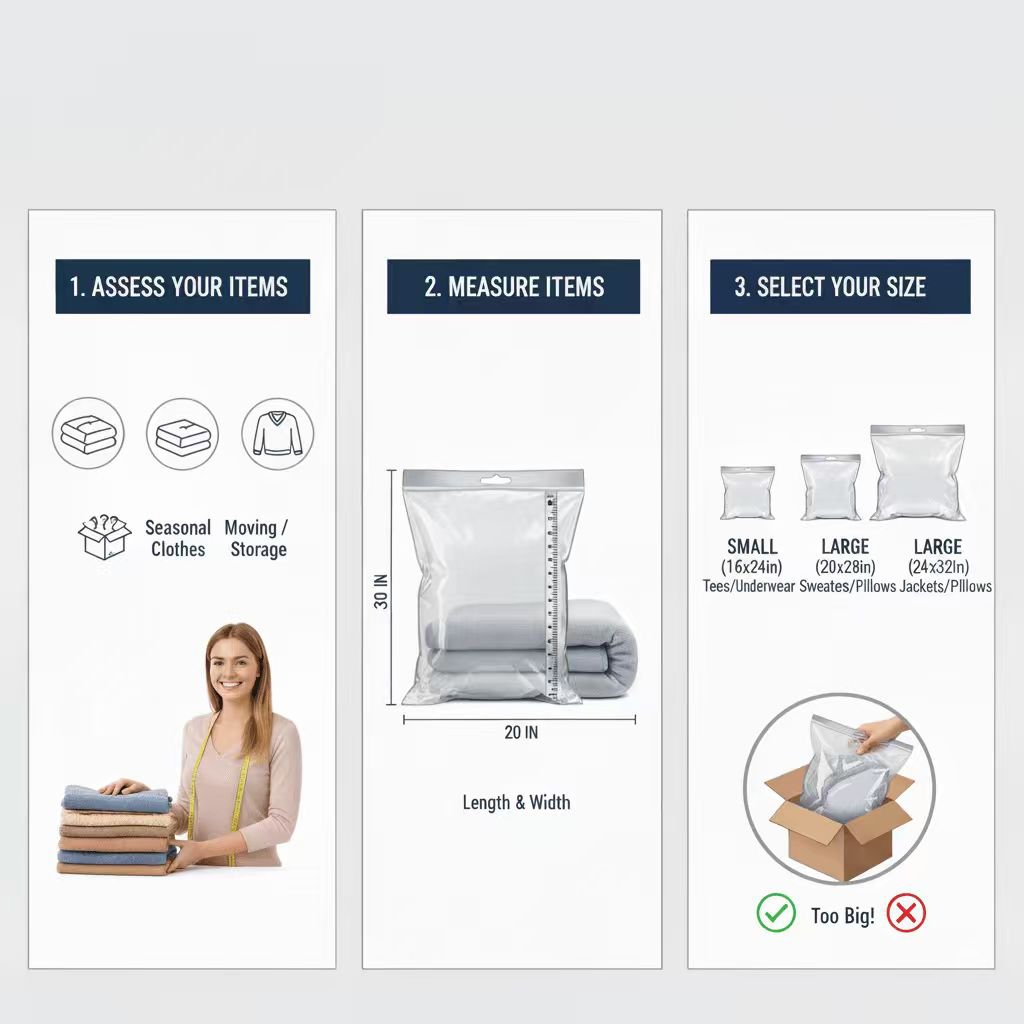

- Size & capacity: Ensure the bag fits your items.

- Material thickness: Thicker film resists puncture and wear.

- Valve/zipper design: One‑way valves and secure zippers matter.

- Reusability: For B2B use, durability is key.

- Intended contents: Food grade bags differ from general storage.

| Buyer decision table | Use case | Must‑have features | Spec to check |

|---|---|---|---|

| Bedding / soft goods | Jumbo size, durable film | 48×35 in+, 90+ micron | |

| Moving/transport | Large volume, rugged build | Weight rating, reuse friendly | |

| Food storage | Food safe, high barrier film | FDA/CE, textured film |

What I look for in my factory

As an OEM factory exporting globally, I demand consistent film quality, custom branding, certifications (e.g., recyclable RPET4), and reliable lead times. That lets me serve large buyers in North America, Europe, Australia.

Takeaway: Match bag specs to need, validate supplier quality, and think long‑term reuse and branding.

Types of Vacuum Seal Bags Explained (Flat, Gusseted, Travel Roll‑Up, Food‑Grade)

Leading paragraph:

“Large vacuum bags” cover many formats. Knowing the types helps you pick and offer the right one.

Snippet paragraph:

Flat, gusseted, roll‑up and food‑grade bags each serve distinct use‑cases—from heavy bedding to compact travel and food preservation.

Dive‑Deeper

Flat (Standard) Bags

These are basic large pouches with one opening and a valve. Good for bedding or seasonal clothes. Pros: simple, cost‑effective. Cons: shape may be irregular.

Gusseted Bags

With expandable sides, these fit bulkier items like pillows or sleeping bags. Pros: better shape fit. Cons: higher cost.

Travel Roll‑Up Bags

Smaller, hand‑pump compatible. Great for luggage or dorms. Pros: portable, no vacuum machine needed. Cons: not heavy‑duty.

Food‑Grade Vacuum Seal Bags

Designed specifically for food—high barrier films, food safe. Pros: extend shelf life. Cons: higher cost, need correct certification.

Takeaway: Choose the type that fits the usage—storage, travel, food—and offer variety in your OEM line.

Best Large Vacuum Seal Bag Brands in 2025: Pros, Cons, and Price Ranges

Leading paragraph:

Many brands compete. As a sourcing buyer you want benchmark brands to compare quality and pricing.

Snippet paragraph:

Top brands vary by film quality, size options, price and customisation. Use them as reference to position your OEM offering.

| Dive‑Deeper | Brand/Product | Price Tier | Pros | Cons |

|---|---|---|---|---|

| Hefty Shrink‑Pak | Mid | Trusted name, good size & seal | Film may not be thickest | |

| MagicBag Instant Space Saver | Value | Good value, reusable | Film thinner, fewer heavy specs | |

| Whitmor Spacemaker Jumbo | Mid/Value | Large size for bedding/dorms | Some durability concerns | |

| Cabela’s Commercial Grade | Premium | Heavy duty, food grade | Higher cost, overkill for casual use | |

| FRANKLIN Storage Bags | Budget | Low cost entry | Less film strength, casual use only |

*Prices reflect US retail; OEM pricing differs in bulk.

Factory strategy: Position your brand at “mid‑premium” with thick film, eco materials (recyclable RPET), custom branding—target large supermarket buyers, fitness brands, promotional clients who demand quality.

Takeaway: Know benchmark brands, identify gaps they don’t cover (custom branding, eco‑friendly film) and position your factory accordingly.

Real‑World Uses Buyers Love: Closets, Bedding, Moving, RVs, and Dorms

Leading paragraph:

Examples help clients see value. Use‑cases clarify why your large vacuum bags matter.

Snippet paragraph:

These bags shine in closet/bedding storage, moving/transport, compact living in RVs or dorms—and work well for your B2B supply clients.

Dive‑Deeper

Closet & Bedding Storage

Seasonal bedding, off‑season clothes, excess inventory—all take space. Vacuum bags compress them, free up room, reduce shipping volume. Ensure dryness and quality film.

Moving / Packing / Logistics

For moves or trade show packing, vacuum bags reduce volume, stack better, protect items from dust and moisture. Offer jumbo sizes and rugged materials for this market.

RVs, Dorms & Compact Living

Tight‑space living demands smart storage. Large vacuum bags help pack bedding, gear, promotional items. Transparent bags with writing panel add value.

How This Relates to Your Export & B2B Model

Since your factory serves big‐company buyers (supermarkets, fitness brands, etc.), you can cross‑sell vacuum bags alongside your shopping/storage bags. Emphasise top quality, custom logo, eco film—so your clients (like Mike Klein) buy from you for their own customers.

Takeaway: Use‑case clarity helps your clients visualise value and drive demand for your product line.

Food Storage Made Safe: What to Seal, What to Skip, and How to Label

Leading paragraph:

Food storage adds another layer of complexity—safety, certification, and correct use matter.

Snippet paragraph:

Vacuum sealing food prolongs shelf life and prevents waste—but you need food‑grade bags, correct usage, labels and safe practices.

Dive‑Deeper

Why vacuum sealing helps food

Removing oxygen slows spoilage and freezer burn5. Barriers reduce moisture ingress. Good for bulk food buyers and supermarkets.

What you can seal

- Meats, fish (bulk/freezer)

- Vegetables/fruits (prefreeze liquids)

- Leftovers/meal‑prep

- Dry goods in large volumes

What you should not seal (or be cautious)

- Sharp‑bone items (may puncture film)

- Liquids (unless pre‐frozen or special bag)

- Delicate fabrics (non‑food storage) may deform under vacuum

- The wrong bag type for the food category

Labeling and reuse tips

- Label: content, date, “use‑by”

- Use food‑grade bags with certifications (FDA, BPA free)

- Educate users: dry items, remove air, proper vacuuming

- Reuse: monitor bag integrity and cleaning

- As manufacturer: offer label zones, custom printing, certification info

Takeaway: Food use requires proper materials and usage. Your factory can add value by offering certified, branded solutions with labeling.

Care, Reuse, and ROI: How to Make Your Bags Last Longer

Leading paragraph:

Durability and reuse drive real value. For your clients and your OEM business, lifecycle matters.

Snippet paragraph:

Proper care extends bag life, improving cost‑per‑use and boosting ROI from both buyer and supplier side.

Dive‑Deeper

Care & maintenance best practices

- Clean and dry before sealing (moisture causes mould)

- Check for holes, weak seals after each use

- Avoid over‑compressing heavy rigid items

- Store sealed bags away from direct sun or extreme heat

- On reuse: release vacuum slowly, inspect condition

- As OEM: print “Max cycles: ___” or reuse guidance on pack

| Reuse & ROI calculation | Metric | Example |

|---|---|---|

| Bag cost | $10 | |

| Estimated reuse cycles | 10 uses | |

| Cost per use | $1 | |

| Alternative cost (space/shipping) | $5 per use | |

| Net saving per use | $4 | |

| Total benefit over 10 uses | $40 |

For your factory, emphasise durability, custom branding and eco materials to raise perceived value and justify factory pricing.

Takeaway: This isn’t just a disposable item—positioning as reusable and durable helps both you and your clients win.

Buyer Checklist & Common Mistakes to Avoid

Leading paragraph:

Even seasoned buyers slip up when sourcing vacuum gel bags—avoid the common traps with a checklist.

Snippet paragraph:

Use this checklist to verify size, material, seal, certification, quality control and avoid mistakes like underspec, non‑food grade or insufficient branding.

Dive‑Deeper

Buyer sourcing checklist

- Size: check uncompressed and compressed dimensions

- Material: film thickness, number of layers, puncture resistance

- Seal/Valve: one‑way valve, double zipper, compatibility

- Certification: food bags must have FDA/CE, BPA‑free

- Reusability claim: check actual cycle life

- Branding: logo print, OEM packaging, export readiness

- Quality Control: pressure/leak tests, uniform film

- Lead time & logistics: on‑time to North America, Europe, etc

- Sustainability angle: recyclable materials, eco film

- Price vs value: adjust for cost per use and durability

Common mistakes to avoid

- Bag too small for intended items

- Thin film that fails early

- Non‑food grade bag used for food

- Sealing damp items—leading to mould

- Over‐compressing unsuitable items (leather, down)

- No clear instructions or labeling—end users misuse

- Ignoring reuse cycle—bag fails after few uses

Takeaway: This checklist helps ensure your sourcing is solid and your product line meets high standards.

Conclusion

Large vacuum seal bags save space, money and protect your goods when correctly specified, sourced and used.

-

Learn how vacuum bags reduce spoilage and enhance item protection. ↩

-

Understand how removing trapped air helps maximize storage space. ↩

-

Discover realistic reuse cycles and how they affect sourcing decisions. ↩

-

See how RPET supports sustainability in vacuum bag production. ↩

-

Find out how vacuum sealing helps preserve food freshness and reduce waste. ↩